If you have any questions, please fill out the contact form at the bottom of the page and contact us.

When it comes to combining innovation, sustainability, and design, Haibo sets the standard in WPC door manufacturing. Choosing the right partner for your interior solutions can make all the difference—and here's why Haibo is the smart choice:

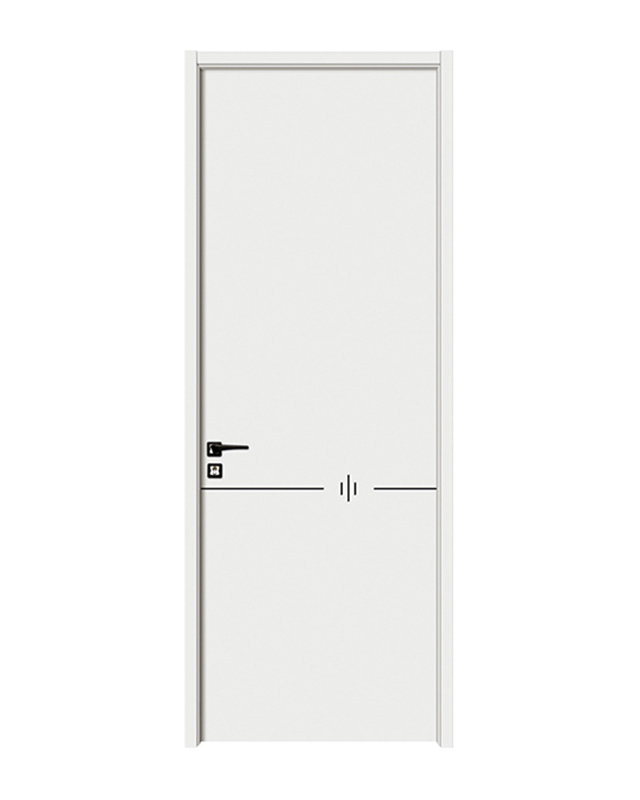

Haibo WPC doors are crafted from high-quality wood-plastic composites, offering great resistance to moisture, warping, termites, and daily wear. They are built to perform in homes, offices, and public spaces alike.

Every space is unique. That's why Haibo provides a wide range of customization options—from door dimensions and textures to color finishes and panel designs. Whether you prefer a sleek modern style or a classic woodgrain look, there's a ideal match waiting.

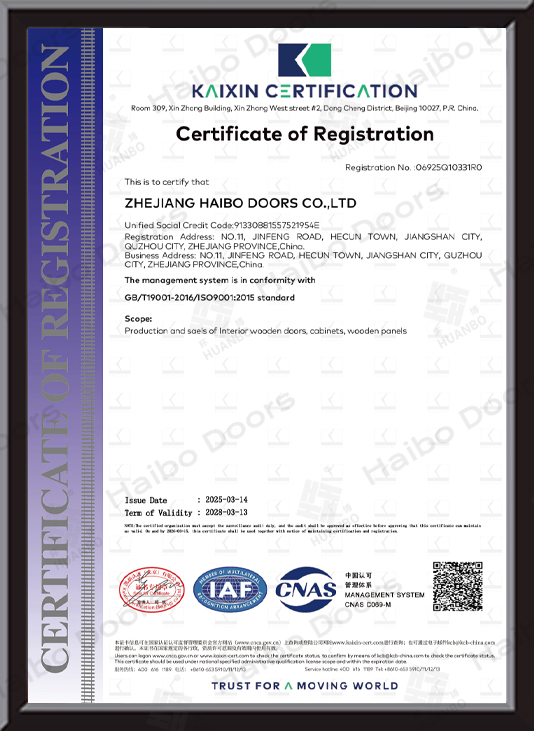

With advanced production facilities and a commitment to quality, Haibo ensures that every door meets strict performance and aesthetic standards. Consistent quality and smooth operation are guaranteed with every unit.

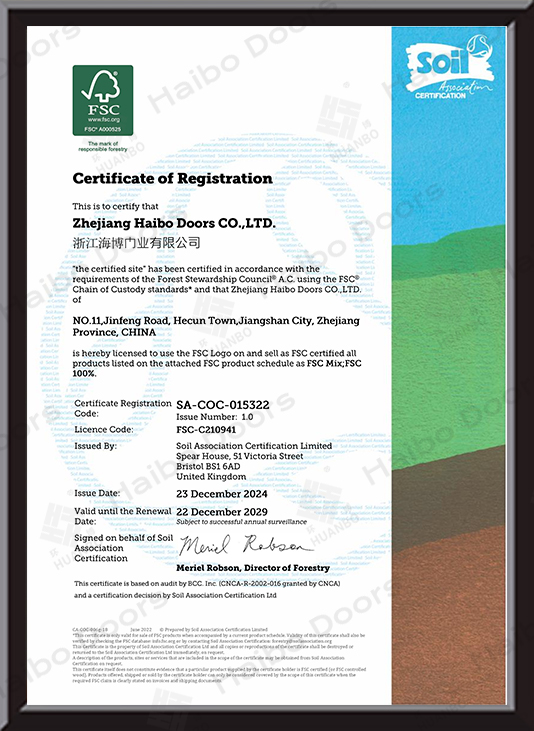

Haibo is committed to sustainability. WPC doors are an eco-friendly alternative to traditional wood, helping to conserve forests while providing the look and feel of natural timber.

From consultation to delivery, Haibo offers responsive, professional service. Whether you're a wholesaler, contractor, or property developer, you'll find a dedicated team ready to support your project needs.

A WPC door is a modern interior or exterior door crafted from Wood-Plastic Composite — a durable material made by blending natural wood fibers with plastic polymers. This combination creates a strong, stable product that maintains the warmth and texture of wood while offering the enhanced durability of plastic.

WPC doors are known for their reliable resistance to moisture, pests, and deformation, making them a smart choice for areas prone to humidity or frequent use. They do not crack, warp, or rot like traditional wooden doors, and require minimal maintenance over time.

Thanks to their structural integrity and customizable appearance, WPC doors are widely used in homes, offices, hotels, and public buildings — offering both aesthetic appeal and long-term performance.

WPC (Wood-Plastic Composite) doors have rapidly gained attention in both residential and commercial design thanks to their smart blend of performance and aesthetics. Here's why they're becoming a top choice:

If you have any questions, please fill out the contact form at the bottom of the page and contact us.

In the global door industry, success is often associated with visible strengths:...

View MoreWalk into any thoughtfully designed space and one detail quietly shapes the enti...

View MoreAn interior door may seem like a quiet background element in a home or commercia...

View MoreFrom Haibo Interior Door Factory standpoint, the choice between minimalist and c...

View MoreInterior doors often fade into the background of homes and offices, quietly open...

View MoreWith growing environmental awareness and continuous advancements in building materials technology, WPC doors (wood-plastic composite doors) manufactured by specialized WPC Door Factory are gaining increasing attention as a new, environmentally friendly door material. Compared to traditional solid wood or PVC doors, WPC doors combine the natural texture of wood with the durability of plastic, offering great waterproof, moisture-proof, and corrosion-resistant properties. Furthermore, they meet the sustainability and environmental requirements of modern architecture. Consequently, WPC doors are increasingly being used in residential, commercial, and public buildings, demonstrating significant market potential.

WPC doors are doors made from Wood Plastic Composite materials, which blend wood fibers or wood flour with thermoplastic resins such as PVC, PE, or PP. This composite material combines the advantages of both wood and plastic, resulting in a product that exhibits the aesthetic appeal and texture of natural wood while maintaining enhanced durability and resistance to moisture, insects, and decay.

The basic composition of WPC materials typically includes:

Unlike traditional wooden doors, WPC doors do not require frequent painting or varnishing and offer better resistance to warping, cracking, and termite damage. Their eco-friendly nature and low maintenance requirements make them an attractive alternative in modern construction.

The manufacturing process of WPC doors involves several key steps that transform raw composite materials into durable, aesthetically pleasing door products. The process typically includes the following stages:

The first step involves selecting and preparing raw materials — wood fibers or wood flour, thermoplastic polymers (usually PVC, PE, or PP), and necessary additives like stabilizers, foaming agents, UV inhibitors, and colorants. These components are carefully weighed and mixed to achieve the desired material properties.

The mixed raw materials are fed into an extruder, where they are heated and melted to form a homogeneous composite mixture. The extrusion process shapes the material into profiles or sheets with specific cross-sections suitable for door components.

Depending on the design, the extruded WPC profiles are cut and assembled or pressed into molds. Some manufacturers use compression molding or injection molding techniques to create door panels with intricate designs and textures. This step may also include foaming processes to reduce weight and improve insulation.

To enhance appearance and durability, surface finishing processes are applied. This can include UV coating, lamination with decorative films, painting, or embossing wood grain textures. These treatments improve the door’s resistance to weathering, scratches, and fading.

The door components — frames, panels, seals, and hardware — are assembled into finished doors. Each door undergoes strict quality control checks for dimensions, surface quality, mechanical strength, and water resistance before packaging and shipment.

The WPC door manufacturing process ensures a balance between strength, aesthetics, and environmental sustainability, making these doors a popular choice in modern construction and renovation projects.