If you have any questions, please fill out the contact form at the bottom of the page and contact us.

A HPL Door, short for High-Pressure Laminate Door, is made by bonding layers of resin-infused paper under high heat and pressure. The result is a strong, smooth surface that’s resistant to scratches, impact, moisture, and heat. These doors are ideal for high-use areas like schools, offices, hospitals, and modern homes.

Why HPL Door Has Gained Popularity

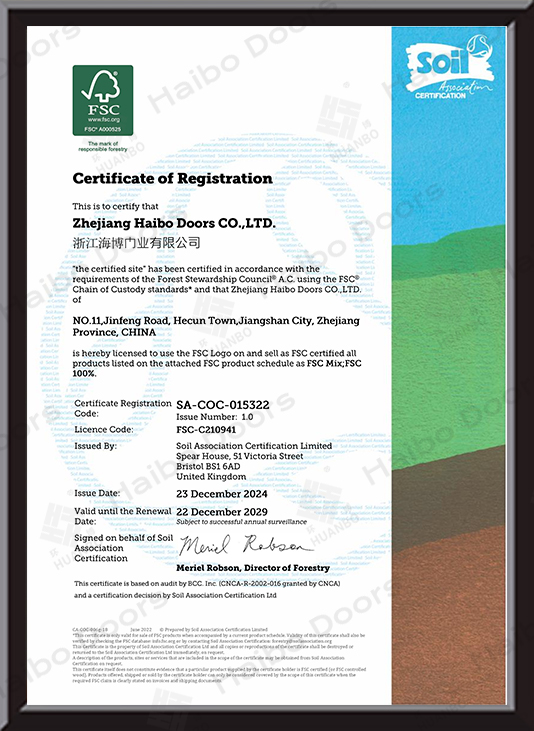

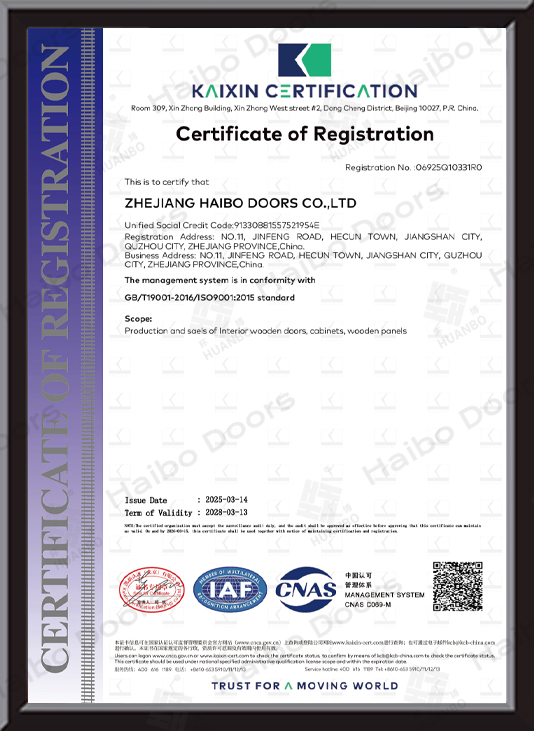

Why Choose Haibo as Your HPL Door Manufacturer

If you have any questions, please fill out the contact form at the bottom of the page and contact us.

Walk into any thoughtfully designed space and one detail quietly shapes the enti...

View MoreAn interior door may seem like a quiet background element in a home or commercia...

View MoreFrom Haibo Interior Door Factory standpoint, the choice between minimalist and c...

View MoreInterior doors often fade into the background of homes and offices, quietly open...

View MoreFitting a PVC interior door from an interior door factory tends to get viewed as...

View MoreWith the growing demand for durable and stylish interior doors, high-pressure laminate (HPL) doors are becoming increasingly popular in residential and commercial construction. HPL doors are renowned for their durable surface finish, resistance to scratches, stains, and impacts, and ease of maintenance. Compared to traditional wooden doors, HPL doors offer increased durability and a wide range of design options, making them an ideal choice for modern construction projects. This article provides an overview of the HPL Door Factory, covering its definition, manufacturing process, key characteristics, market applications, and future trends.

HPL doors are doors that feature a surface layer made from High Pressure Laminate, which is created by pressing multiple layers of resin-soaked paper under high heat and pressure. This surface layer is then bonded to a core material such as MDF (medium-density fiberboard), particleboard, or plywood to create the finished door.

The basic composition of HPL doors includes:

Compared to traditional wood doors, HPL doors offer reliable resistance to wear and tear, minimal maintenance, and greater design flexibility, making them a favored option for both interior and commercial use.

The manufacturing process of HPL doors involves several important steps that ensure the final product is both durable and aesthetically pleasing:

High Pressure Laminate sheets are produced by impregnating layers of kraft paper and decorative paper with resins, which are then compressed under high heat and pressure. This process creates a hard, durable surface that can withstand scratches, stains, and impacts.

The door core is prepared from materials such as MDF, particleboard, or plywood. These materials are cut and shaped according to the door design specifications to provide the necessary strength and stability.

The HPL sheets are bonded to the core using specialized adhesives under heat and pressure. This ensures a strong and seamless bond between the laminate surface and the core, preventing delamination and enhancing durability.

After lamination, the door edges are trimmed, and any additional machining (such as cutting out for hardware installation) is completed. Finally, each door undergoes rigorous quality control checks, including tests for surface finish, adhesion strength, and dimensional accuracy.

This comprehensive manufacturing process results in doors that are not only visually appealing but also resilient and long-lasting.

HPL doors offer a practical and stylish solution that meets modern demands for durability, design versatility, and low maintenance, making them a strong contender in the evolving interior door market.