The wall panel market has evolved far beyond its utilitarian origins. Today, it’s a creative space where materials, textures, and styles intersect to form a visual statement—one that Haibo’s Wall Panel Factory is uniquely equipped to deliver. From minimalistic interiors to luxury commercial lobbies, our wall panels are quietly shaping some of the stylish spaces in modern architecture.

From Raw Board to Refined Surface

At the core of our process is structural excellence. Every wall project begins with a careful selection of materials, whether MDF panels, plywood, or high-performance concrete. Our factory conducts testing and humidity control from the outset, ensuring consistent measurements over time.

Once the results are analyzed, the production process begins with tooling, which precisely shapes grooves, grooves, or three-dimensional shapes. These machines are operated by skilled technicians, enabling us to continue producing the sophisticated products demanded by our modern customers.

Here’s a breakdown of our core production phases:

| Phase | Focus | Tools Used |

|---|---|---|

| Material Prep | Moisture & density control | Moisture meters, scanners |

| Pattern Milling | Decorative cuts | CNC routers |

| Surface Finishing | Smoothness & protection | UV coating lines |

| Quality Check | Durability & uniformity | Calipers, inspection lines |

Each step is backed by a strong commitment to consistency, but we also allow space for flexibility—because design trends are always moving.

Textures and Trends: What Clients Are Choosing

A growing number of clients today seek texture-rich, tactile designs that elevate flat walls into features. At Haibo, we’ve seen rising demand for the following finishes:

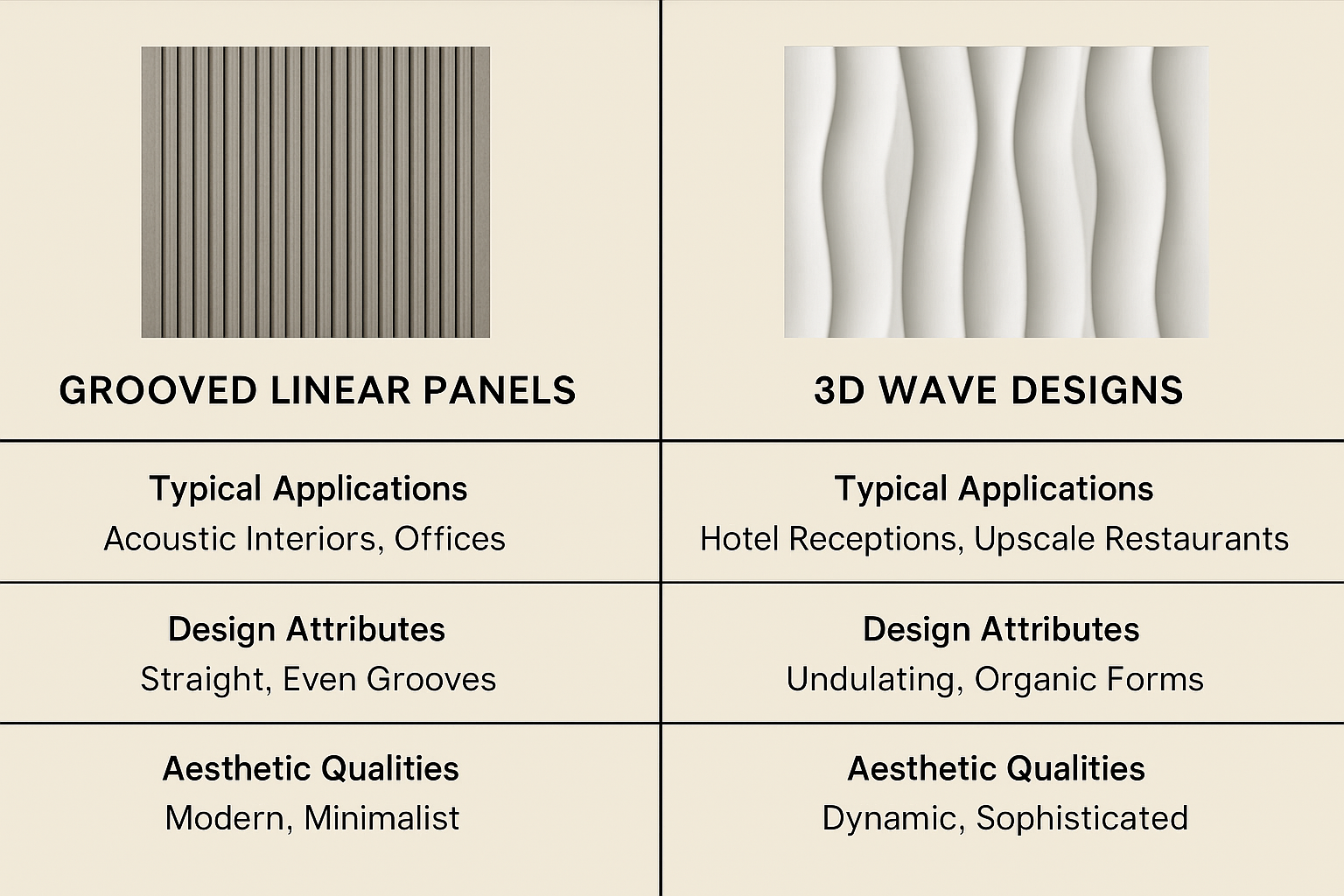

- Grooved Linear Panels – Ideal for acoustic interiors in home theaters or offices

- 3D Wave Designs – A favorite in hotel receptions and upscale restaurants

- Marble & Concrete Laminates – For a sleek industrial aesthetic without the weight

- WPC Slatted Systems – A sustainable, moisture-resistant option for bathrooms and spas

These styles are not only visually appealing but are engineered to perform under varying temperature and humidity levels—an essential feature in both residential and commercial environments.

Why Designers and Contractors Prefer Haibo

Unlike many manufacturers that offer limited customization, our wall panel factory thrives on creative collaboration. You can specify:

- Dimensions (thickness from 6mm to 18mm)

- Color tones (neutrals, woodgrain, RAL-customized)

- Surface treatments (matte, glossy, embossed)

- Edge profiles (V-groove, square, micro-bevel)

For larger projects, we even support on-site consultation and prototyping. Our team can help architects test new finishes or build sample installations before final production begins.

Built for the Future: Automation Meets Sustainability

Another point of pride is how our facility balances scale with sustainability. We’ve integrated smart control systems to minimize waste, reduce offcuts, and recycle sanding dust. Our UV finishing line emits significantly fewer VOCs compared to traditional spraying methods.

Looking ahead, we’re investing in AI-powered surface inspection to detect micro-defects, ensuring every panel meets the aesthetic and structural standards expected by high-end clientele.

-

As the demand for visually rich, performance-oriented interiors grows, Haibo’s Wall Panel Factory continues to serve as both a design partner and technical powerhouse. Whether you're fitting out a private home or a luxury chain hotel, our wall panels offer the right balance of style, function, and reliability. Explore more or get in touch with our team at: www.haibodoor.com

English

English русский

русский Français

Français Español

Español Indonesia

Indonesia عربى

عربى