Wooden doors have long been a staple of interior design, known for their warmth, durability, and natural beauty. But today’s wooden doors are more than just traditional panels—they're the result of advanced craftsmanship, sustainable practices, and creative customization. At the heart of it all is the modern wooden door factory, where innovation meets wood in the really satisfying way.

If you’ve ever wondered how that perfectly polished oak or walnut door in your home came to be, the answer lies in a process that's both technical and artistic. Here’s what makes today’s wooden door factories stand out—and why more people are paying attention.

Why Wooden Doors Still Matter

While the market is full of materials like PVC, metal, and composite, wood remains a favorite among designers and homeowners alike. Why?

- It adds character and texture to any space.

- It's durable when treated properly.

- It provides natural sound insulation.

- It’s renewable—especially when sourced from responsibly managed forests.

Today’s wooden door factory embraces all of this while adding smarter production methods to increase efficiency and consistency.

What Happens Inside the Factory

Step into a factory and you’ll see more than just stacks of timber. You’ll find laser cutters, CNC routers, automatic sanding lines, and moisture control systems working in sync. Here's a quick snapshot of how production has evolved:

| Feature | Traditional Factory | Modern Wooden Door Factory |

| Cutting Method | Manual | CNC Precision Cutting |

| Coating Process | Hand Spray | Automated UV Coating |

| Material Sourcing | Local, Unregulated | FSC-Certified Sustainable Timber |

| Design Options | Limited | Fully Customizable |

| Waste Management | Minimal | Integrated Eco-Control Systems |

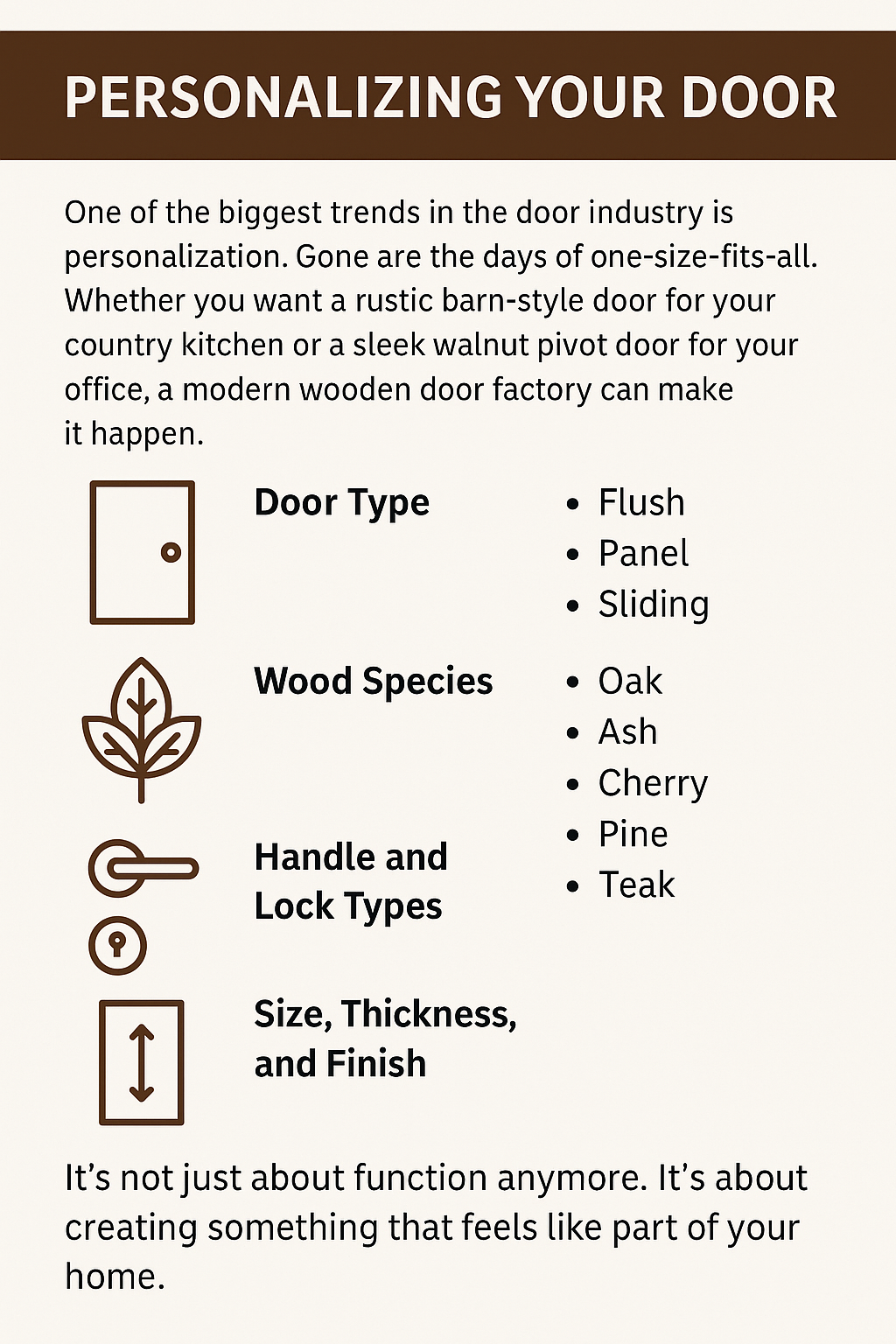

Customization: It's Personal Now

One of the biggest trends in the door industry is personalization. Gone are the days of one-size-fits-all. Whether you want a rustic barn-style door for your country kitchen or a sleek walnut pivot door for your office, a modern wooden door factory can make it happen.

Clients can now select:

- Door type (flush, panel, sliding, glass inserts)

- Wood species (oak, ash, cherry, pine, teak)

- Handle and lock types

- Size, thickness, and finish

It’s not just about function anymore. It’s about creating something that feels like part of your home.

Don’t Forget Color

The color of a door might seem like a small detail—but it makes a big visual difference. Factories today offer an expanded palette that goes beyond classic wood tones.

Popular choices include:

- Warm walnut for cozy interiors

- Pure white for clean, minimalist spaces

- Charcoal grey for an industrial edge

- Muted green or blue for a calming touch

With modern coatings and UV protection, these colors are built to last—no fading, peeling, or cracking.

Where Craft Meets Commitment

Great wooden doors don’t just happen. They’re planned, crafted, tested, and perfected. That’s the promise of a reliable wooden door factory: to deliver not only a beautiful product, but also a smooth, professional experience from start to finish.

Whether you're renovating, building new, or outfitting a commercial project, choosing the right door—and the right team behind it—makes all the difference. To learn more or explore our latest styles and production capabilities, visit us wooden door factory at: www.haibodoor.com

English

English русский

русский Français

Français Español

Español Indonesia

Indonesia عربى

عربى