When you close a door at home, it's easy to overlook the craftsmanship behind it. Yet, each interior door carries with it a journey that begins in the factory, where raw timber is transformed into a refined, functional element of design. The process inside an interior door factory is a blend of tradition and innovation, combining natural materials, advanced equipment, and customization to meet the demands of modern living.

1. Material Selection: Choosing the Foundation

The beginning step in the production process is material selection. A reliable interior door factory typically works with several core materials including solid hardwood, MDF (medium-density fiberboard), HDF (high-density fiberboard), and sometimes engineered wood. The choice depends on the application—flush doors, panel doors, sliding doors, or those incorporating decorative glass.

- Material is kiln-dried to reduce moisture content and improve durability. Quality control teams inspect timber for knots, splits, or warping. Only the selected materials move on to the next phase, ensuring longevity and aesthetic appeal.

| Material Type | Appearance | Durability | Cost | Common Use |

|---|---|---|---|---|

| Solid Wood | Natural Grain | High | High | Premium Doors |

| MDF | Smooth | Medium | Low | Painted Doors |

| HDF | Very Smooth | High | Medium | High-Traffic Areas |

| Engineered Wood | Variable | Medium | Medium | Budget Projects |

2. Machining and Shaping: Precision through Technology

Once the wood is selected, it enters the cutting and shaping phase. Advanced CNC machines achieve precision that is impossible to achieve by hand. The wood is cut, sawn, and ultimately made into boards, strips, and columns. Complex shapes and profiles are carved into panel doors, sometimes with custom patterns based on customer requirements.

Milling machines can create door trims and glass inserts with high precision, adding grooves or embossing to enhance texture. High productivity is essential at this stage for factories that handle large volumes and maintain batch consistency.

3. Assembly: Building the Structure

Next comes the assembly phase, where the individual components are glued together. Adhesives and fastening systems are used to create strong joints and additional reinforcement is applied where necessary. The door frame (whether solid block, tubular or beam) is inserted into the door frame and securely sealed. The door frame determines the sound insulation, weight and price of the door.

Glass elements, if required, are added at this stage. Each opening is lined, sealed, and tested to prevent air leakage and moisture penetration.

4. Surface Finishing: Customization and Protection

The surface treatment is a fusion of creativity and environmental protection. Customers can choose from a variety of finishes, including veneer, paint, laminate, PVC or melamine film. This step is not only aesthetically pleasing, but also enhances moisture, heat and scratch resistance.

Color selection is crucial to customer satisfaction. Warm cherry wood tones or matte gray are preferred. The finish is sprayed with an automatic spray system and then UV-cured or air-dried depending on the material.

Some factories offer color-matching services, enabling clients to coordinate doors with other interior elements. This is increasingly important in custom homes and commercial projects, where cohesion in design is essential.

| Finish Type | Visual Style | Scratch Resistance | Water Resistance | Popular Shades |

|---|---|---|---|---|

| Veneer | Natural Wood | Medium | Low | Oak, Teak |

| Laminate | Matte/Shiny | High | Medium | White, Grey |

| PVC Wrap | Glossy/Smooth | High | High | Walnut, Maple |

| Paint | Any | Medium | Low | Custom Colors |

5. Inspection and Quality Control: Ensuring Excellence

Before any door leaves the facility, it undergoes a rigorous quality inspection. This includes checking for visual flaws, verifying dimensions, testing hinge alignment, and assessing the surface finish. Scratches, uneven paint, or warping are not tolerated.

Sound insulation and fire rating tests may also be conducted for specialized products. Top-tier factories often have in-house labs or partnerships with third-party certifiers to ensure compliance with regional standards.

6. Hardware Integration and Packaging

At this point, hardware such as hinges, locks, and handles may be pre-installed or packaged separately based on customer preference. Pre-drilled holes and mounting plates are added to reduce installation time on-site.

| Hardware Item | Pre-Fitted Option | Customer Installed Option | Finish Choices |

|---|---|---|---|

| Hinges | Y | Y | Chrome, Brass |

| Locksets | Y | Y | Matte Black, Nickel |

| Handles | N | Y | Bronze, Steel |

Doors are then packaged with edge protectors and moisture-resistant wraps. Labels include barcodes or QR codes for easier logistics management and tracking.

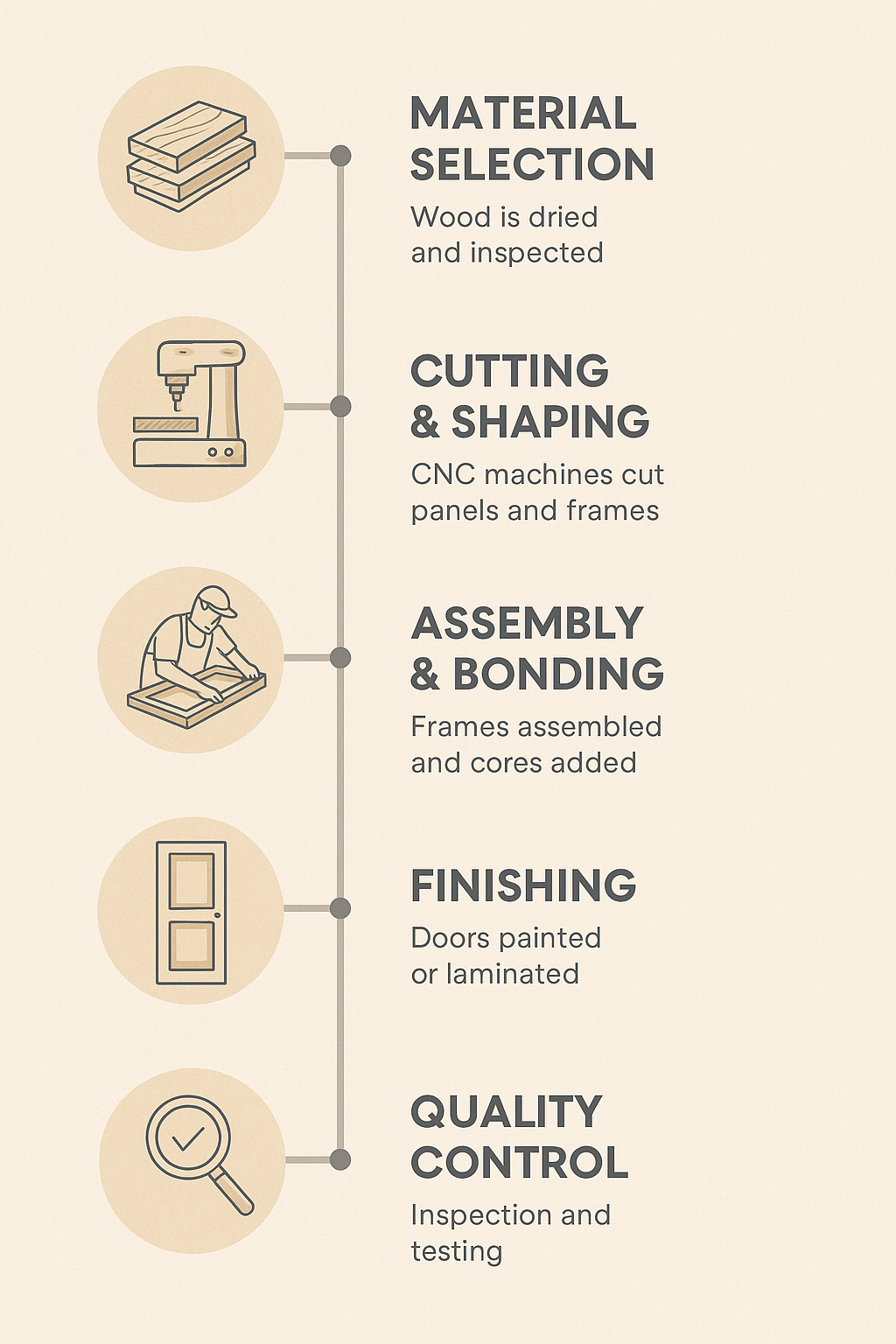

The Production Process at a Glance

| Production Stage | Tasks and Tools | Purpose |

|---|---|---|

| Material Selection | Kiln drying, inspection, grading | Durability and consistency |

| Cutting and Shaping | CNC, routing, embossing | Precision and design flexibility |

| Assembly and Bonding | Frame building, core filling, glass sealing | Structural integrity and customization |

| Finishing | Painting, laminating, UV curing | Aesthetics and protection |

| Quality Control | Dimension checks, surface inspection | Product excellence |

| Hardware & Packaging | Hinge fitting, labeling, wrapping | Ease of installation and delivery |

Blending Tradition with Modern Expectations

The modern interior door factory is a testament to how traditional craftsmanship can thrive in an age of mass production. Whether producing classic flush doors or bold contemporary panels, factories are evolving to meet high expectations of quality, style, and sustainability. With customization and material innovation becoming the norm, today's interior doors are not just functional—they are central to the identity of a space.

For buyers and designers alike, understanding the process inside an interior door factory offers insight into what separates a standard door from one that truly enhances an interior environment.

If you have any further questions or need more information beyond the common queries discussed about PVC Interior Door , feel free to visit our factory at Zhejiang Haibo Door Co., Ltd. or check out our website at haibodoor.com. Our team will be happy to assist you and provide prompt answers to any inquiries you may have.

English

English русский

русский Français

Français Español

Español bahasa Indonesia

bahasa Indonesia عربى

عربى